Brief Guide to Installing a Permanent Magnet Alternator Generator

Are you prepared to embark on a journey that will revolutionize the way you think about power generation? Installing a Permanent Magnet Alternator Generator may seem like a daunting task, but fear not, for with the right guidance and knowledge, you can successfully harness the energy of nature in your own hands.

Stay tuned to uncover the essential steps and tips that will empower you to create your very own sustainable energy solution.

Key Takeaways

- Evaluate site location for optimal wind conditions and accessibility.

- Implement proper conversion and regulation setup for efficient power generation.

- Prioritize safety measures, grounding, and backup power system integration.

- Continuously optimize and upgrade the system for maximum efficiency and performance.

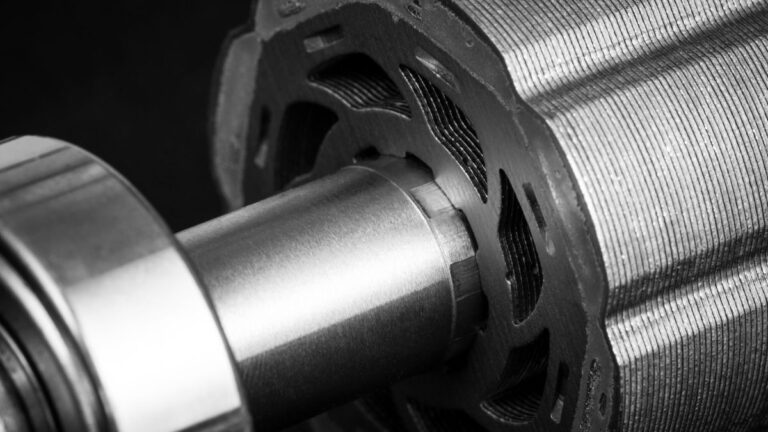

Permanent Magnet Alternator Overview

When looking at Permanent Magnet Alternators (PMAs), it becomes evident that they revolutionize electricity generation by leveraging magnets instead of field coils.

These compact alternators are ideal for small wind turbine applications due to their efficiency and ability to produce 3-phase AC power. Operating at low rotational speeds, PMAs are tailored for wind power generation, offering a simplified design without field coils for easier maintenance.

The generated AC power requires rectification for practical use, making PMAs a versatile choice for renewable energy projects. Their innovative construction allows for a more straightforward setup compared to traditional alternators, providing a reliable source of electricity for your DIY wind generator system.

Understanding Voltage Ratings

To comprehend the significance of voltage ratings in Permanent Magnet Alternators (PMAs), it’s crucial to grasp their role in determining the starting point for power generation efficiency. When dealing with PMAs, understanding voltage ratings is essential for optimizing power output and ensuring efficient energy conversion.

Here are key points to consider:

- Power Output: Voltage ratings directly impact the power output capabilities of PMAs.

- Thicker Wire: Higher voltage ratings may require thicker wire gauges to handle the increased power.

- Surface Area: Voltage ratings affect the surface area of the coils, influencing the efficiency of power generation.

- Strong Winds: Higher voltage ratings might be necessary to start power generation in areas with stronger winds.

For detailed guidance on voltage ratings and other technical aspects, consider seeking expert technical support.

External Rectification Setup

Understanding the significance of external rectification setup is crucial in the installation of a Permanent Magnet Alternator Generator. It involves converting the alternator’s AC output to usable DC power for various applications.

The first thing to consider is connecting the output of the alternator to a rectifier for converting AC to DC power. This setup is essential for charging batteries or powering devices. It must be easy to understand and strong enough to handle the power output.

External rectification provides better control and regulation of the DC output voltage, ensuring a stable power supply. Properly sizing and selecting the rectifier based on the system requirements and voltage levels needed is crucial for efficient power conversion and utilization.

Related Post: How To Turn A Car Alternator Into A Generator.

Power Management Controller Installation

The installation of the power management controller for a Permanent Magnet Alternator Generator involves connecting it strategically between the alternator and the load. When setting up your PMAG system, consider the following key points for the power management controller installation:

- Regulates Voltage Output: Ensures stable voltage suitable for charging batteries or powering devices.

- Connection Placement: Should be connected between the alternator and the load for effective control.

- Additional Features: Some controllers offer over-voltage protection and monitoring capabilities.

- Essential for Efficiency: Proper installation is crucial for safe and efficient operation of the PMAG system. Make sure to follow the manufacturer’s guidelines for optimal performance.

Selecting the Right Model

When selecting the right model of alternator for your wind turbine system, prioritize evaluating the required power output and voltage range of your application. Consider the cut-in speed, operating RPM range, torque capabilities, size, and weight of different alternator models to ensure compatibility.

Seek expert advice or consult with manufacturers like Hurricane for guidance in choosing the appropriate permanent magnet alternator model for your DIY project.

| Considerations | Alternator Model Selection Tips |

|---|---|

| Power Output | Evaluate power needs accurately |

| Voltage Range | Ensure compatibility |

| Cut-in Speed | Match with wind conditions |

| Torque Capabilities | Drive generator efficiently |

| Size and Weight | Fit within design parameters |

Power Output Characteristics

To maximize the efficiency of your power generation system with a Permanent Magnet Alternator Generator, it’s essential to carefully consider the power output characteristics influenced by the winding type and configuration.

- Winding Type: Different winding configurations affect power output efficiency.

- Voltage Regulation: External voltage regulation may be necessary for consistent power delivery.

- Cut-in RPM: Understanding the cut-in RPM is crucial for optimal power generation.

- Torque Requirements: Proper torque management is essential for maximizing power output efficiency.

Dealing With Cogging and Torque

Properly managing cogging and torque is crucial for optimizing the performance of a Permanent Magnet Alternator Generator. To reduce cogging, precise machining and efficient magnetic saturation techniques are essential. Cogging impacts the ease of startup and efficiency under load conditions.

Adequate torque is necessary to drive the alternator efficiently for power generation. Addressing cogging through meticulous design and construction can significantly enhance overall performance. Minimizing cogging effects leads to smoother operation and improved power output in the alternator system.

Hurricane PMA Models

Addressing cogging and torque considerations is crucial when selecting from Hurricane’s PMA models like the Cat IV V, White Lightning, and Air Boss for your power generation requirements.

- Cat IV V, White Lightning, and Air Boss models offer efficient power generation solutions.

- Each model is optimized for specific power output needs.

- Hurricane PMA models are designed for DIY enthusiasts seeking reliable AC generation.

- Specifications and support are provided for selecting the right model for your project.

Customer Service and Guidance

For those embarking on the installation of a Permanent Magnet Alternator Generator, Hurricane’s customer service and guidance offer invaluable support and expertise.

When you choose Hurricane for your PMA needs, you gain access to a team dedicated to helping you select the right model and navigate the technical aspects of installation. Here is a glimpse of the assistance Hurricane provides:

| Customer Service Features | Description | Benefits |

|---|---|---|

| Expert Model Selection | Get help choosing the right alternator model for your needs | Ensures optimal performance |

| Technical Support | Assistance in understanding specifications and installation requirements | Smooth installation process |

| Troubleshooting Help | Guidance in resolving any issues or questions during installation | Minimizes downtime |

Hurricane’s commitment to customer service ensures your DIY project is supported every step of the way.

Setting Up Power Generation Systems

To set up a power generation system incorporating a Permanent Magnet Alternator Generator, assess the optimal installation location based on wind conditions and solar panel access. Consider these crucial steps:

- Determine the best location for installation based on wind and sunlight availability.

- Ensure proper grounding and electrical safety measures are in place during the setup.

- Implement a backup power system using batteries or a grid tie system to store excess energy.

- Regularly monitor and maintain the system for optimal performance and longevity.

Following these steps will help you create a reliable and efficient power generation system with your Permanent Magnet Alternator Generator.

Related Post: How to Build Your Own Alternator Permanent Magnet Generator.

Frequently Asked Questions

Where Are the Magnets of a Permanent Magnet Alternator Installed?

The magnets in a permanent magnet alternator are typically installed on the rotor assembly. They create a magnetic field interacting with stator windings for electricity generation. Proper alignment, spacing, and orientation impact efficiency and power output.

What Are the Disadvantages of a Permanent Magnet Generator?

Disregard the allure of ease; permanent magnet generators bring limitations. Expect power output constraints, efficiency woes at high speeds, sensitivity to temperature shifts, cogging struggles, and demanding maintenance needs. Fully grasp the downsides before diving in.

What Is the Difference Between a Permanent Magnet Generator and an Alternator?

In a permanent magnet generator, magnets create the magnetic field; alternators use field coils. Permanent magnet generators are compact, lighter; they may have built-in rectifiers. Alternators often need external rectification. Both produce AC power differently.

Can a Permanent Magnet Motor Be Used as a Generator?

Yes, a permanent magnet motor can be utilized as a generator. When rotating the motor’s shaft, it induces electricity in the stator windings, producing alternating current. The output’s voltage and current depend on rotation speed and motor design.

Conclusion

Now that you have successfully installed your Permanent Magnet Alternator Generator, you’re ready to start generating your own electricity.

Did you know that by using renewable energy sources like a PMA, you can reduce your carbon footprint by up to 90% compared to traditional fossil fuel-based power generation methods?

Take pride in knowing that you’re making a significant impact on the environment while enjoying a sustainable energy solution.