12 Essential Dimensions for Magnetic Field Generators

Are you curious about the key dimensions for magnetic field generators? Have you ever wondered how these dimensions affect the performance and efficiency of these generators?

Well, in this discussion, we will investigate the truth behind the theory that there are 12 essential dimensions that play a crucial role in the functioning of magnetic field generators.

From the overall size and core diameter to the wire gauge and power input, we will dive into each dimension and explore how it contributes to the generation of magnetic fields.

So, if you want to uncover the secrets behind these essential dimensions and understand their significance, stay tuned for an illuminating exploration ahead.

Key Takeaways

- The overall size of a magnetic field generator is an important factor to consider, as it will determine the space requirements for installation.

- The core diameter and material selection play a crucial role in determining the efficiency and performance of the generator.

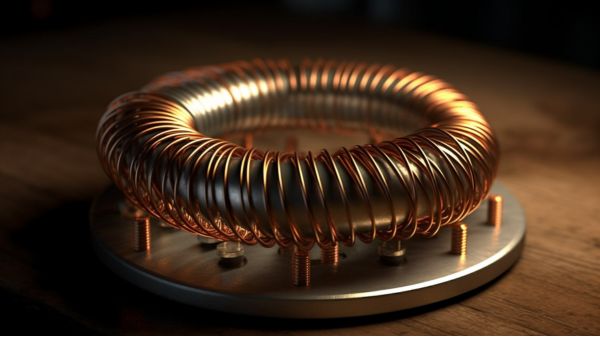

- The number of turns and coil windings in the generator’s coil will affect the strength and stability of the magnetic field produced.

- The magnetic field properties, such as the magnetic flux density, induced voltage, gap distance, pole diameter, and magnet strength, all contribute to the overall functionality and effectiveness of the generator.

Overall Size

The overall size of magnetic field generators can vary significantly depending on their intended use, ranging from small, portable devices to large, industrial-scale systems.

The dimensions of magnetic field generators play a crucial role in their installation and integration into different applications.

When it comes to magnetic field generators, size matters. The overall size impacts the generator’s mobility, ease of maintenance, and practicality for specific environments.

Smaller generators are easier to transport and maneuver, making them ideal for portable applications such as medical devices or scientific experiments.

On the other hand, larger generators are designed for industrial-scale applications where a stronger magnetic field is required, such as in manufacturing or energy production.

Understanding the overall size of magnetic field generators is essential for designing and implementing them effectively across various industries.

Core Diameter

To optimize the performance of your magnetic field generator, it’s crucial to consider the optimal core size and the selection of the core material.

The core diameter directly affects the strength and stability of the magnetic field produced. By choosing the appropriate core diameter, you can generate a magnetic field with the desired characteristics, ensuring efficient and effective operation of the generator.

Optimal Core Size

Maximizing efficiency and performance in magnetic field generators requires careful consideration of the optimal core size, a critical factor that directly influences magnetic field strength and the ability to produce desired magnetic flux.

The optimal core size, usually measured by its diameter, plays a significant role in determining the generator’s overall performance. A larger core diameter can increase the magnetic field strength and efficiency of the generator, resulting in a more powerful and effective magnetic field.

However, it’s important to note that the optimal core size may vary depending on the specific application and design requirements. Selecting the right core size is crucial for achieving the desired magnetic field characteristics and ensuring the generator operates at its peak efficiency.

Therefore, comprehensive analysis and evaluation should be conducted to determine the optimal core size for each magnetic field generator, ultimately leading to improved efficiency and performance.

Core Material Selection

Core material selection, specifically the choice of core diameter, plays a crucial role in determining the performance and efficiency of magnetic field generators. The diameter of the core material directly affects the magnetic flux capacity and its ability to handle higher levels of magnetic induction. Here are three key reasons why core diameter selection is of utmost importance:

- Enhanced Power Handling: Larger core diameters allow for higher power handling capabilities, enabling the generator to efficiently generate stronger magnetic fields. This is particularly beneficial when powering large-scale machinery or equipment.

- Reduced Core Losses: Optimal core diameter selection helps reduce core losses, resulting in improved overall efficiency and reduced energy wastage. This ensures maximum utilization of the generated magnetic field.

- Size and Weight Optimization: The choice of core diameter significantly influences the overall size and weight of the magnetic field generator. By selecting the appropriate core diameter, you can achieve the desired magnetic field strength without compromising on portability or space constraints.

Coil Length

The length of the coil significantly impacts the strength and distribution of the magnetic field it generates. Longer coils tend to produce a stronger magnetic field due to increased wire turns and higher inductance. This is because the length of the coil affects the efficiency and performance of the magnetic field generator.

By increasing the length of the coil, more wire turns can be added, resulting in a higher magnetic field strength. Additionally, the size and shape of the coil can influence the direction and uniformity of the magnetic field it generates.

Therefore, understanding the relationship between coil length and magnetic field strength is crucial for designing and optimizing magnetic field generators. By carefully selecting the appropriate coil length, you can achieve the desired strength and distribution of the magnetic field for your specific application.

Wire Gauge

When considering the design of magnetic field generators, an important factor to consider after coil length is the wire gauge. Wire gauge determines the size and diameter of a wire, influencing its electrical resistance and current-carrying capacity.

Here are three key points to keep in mind regarding wire gauge:

- Safety: Selecting the right wire size is crucial for electrical applications to ensure safety. Choosing an inadequate wire gauge can result in overheating, voltage drops, and potential hazards. It’s essential to understand the current requirements of the system and match it with the appropriate wire gauge to prevent accidents.

- Efficiency: Proper wire gauge selection also affects the efficiency of the magnetic field generator. Using a wire gauge that’s too small may cause excessive resistance, leading to energy losses and reduced performance. Conversely, a wire gauge that’s too large can be unnecessary and inefficient, resulting in increased costs.

- Application-specific: Different wire gauges have specific applications. Larger gauges are suitable for high current loads, making them ideal for heavy-duty applications. On the other hand, smaller gauges are more appropriate for lower current loads, such as control circuits or signal transmission.

Understanding wire gauge is crucial for achieving optimal performance, safety, and efficiency in magnetic field generator designs. Take the time to select the appropriate wire gauge to ensure liberation from potential limitations and maximize the generator’s potential.

Number of Turns

The number of turns in a coil is a critical factor in determining the strength of the magnetic field generated. Increasing the number of turns in a coil directly increases the magnetic flux density, resulting in a more powerful magnetic field.

This, in turn, leads to a higher induced voltage, making the number of turns a crucial parameter for optimizing the efficiency and power output of electromagnetic generators.

Coil Windings

Increasing the number of turns in coil windings enhances the strength and efficiency of the magnetic field generated. The number of turns in coil windings directly affects the induced electromotive force and current flow.

As you strive for liberation in your magnetic field generator, consider the following:

- More turns in the coil windings result in a stronger magnetic field, allowing for greater control and manipulation of magnetic forces.

- Increasing the number of turns enhances the efficiency of the magnetic field generator, ensuring optimal performance and energy utilization.

- The specific application and desired magnetic field strength should guide the determination of the optimal number of turns in the coil windings.

Magnetic Flux Density

To optimize the performance and efficiency of a magnetic field generator, it’s essential to carefully consider the magnetic flux density, which is determined by the number of turns in the coil windings.

Magnetic flux density, also known as the number of turns, is a measure of the quantity of magnetic field lines passing through a given area. It plays a crucial role in the functioning of the generator because it directly affects the strength of the magnetic field.

By increasing the number of turns in the coil, the magnetic flux density is increased, resulting in a stronger magnetic field and higher induced voltage. This relationship between the number of turns and magnetic flux density is vital in designing and optimizing magnetic field generators for various applications.

Therefore, understanding and controlling the magnetic flux density is essential for achieving the desired performance and efficiency of a magnetic field generator.

Induced Voltage

Understanding the relationship between magnetic flux density and the number of turns in a coil allows for the optimization of induced voltage in a magnetic field generator. The induced voltage in a coil is directly proportional to the number of turns in the coil. By increasing the number of turns in a coil, the strength of the induced voltage can be enhanced. This relationship is governed by the equation EMF = -N(dΦ/dt), where N represents the number of turns in the coil and Φ denotes the magnetic flux. Adding more turns in the coil leads to a greater change in magnetic flux, resulting in a higher induced voltage.

Recognizing this fundamental aspect of electromagnetic induction allows for the liberation of design possibilities and the optimization of induced voltage in magnetic field generators.

- Increased number of turns in a coil unlocks higher induced voltage potentials.

- Optimizing the number of turns allows for enhanced efficiency and performance.

- The ability to control the number of turns empowers engineers to fine-tune induced voltage output.

Magnetic Flux Density

Magnetic flux density, denoted as B, is a crucial parameter in the design and operation of magnetic field generators. Measured in tesla (T), it quantifies the strength of a magnetic field. B determines the force exerted on charged particles within the field.

Unlike magnetic field strength (H), which considers only the medium, B takes into account both the medium and magnetization. Understanding magnetic flux density is essential for the effective functioning of magnetic field generators. It plays a vital role in various technological applications.

Accurate measurement and control of B are necessary for achieving desired outcomes. By manipulating magnetic flux density, you can optimize the performance of magnetic field generators and enhance their efficiency. Therefore, a thorough understanding of B is crucial for engineers and researchers in the field of magnetic field generation.

Gap Distance

The gap distance, an essential parameter in magnetic field generators, directly influences the strength and uniformity of the magnetic field produced. Understanding and optimizing the gap distance is crucial for the proper functioning of magnetic field generators. Here are three significant aspects of the gap distance that you need to consider:

- Magnetic Field Strength: A smaller gap distance generally leads to a stronger magnetic field. By minimizing the distance between the magnetic poles, you can increase the magnetic flux density and enhance the overall performance of the generator.

- Uniformity: Maintaining a consistent gap distance ensures a more uniform magnetic field distribution. Irregular gaps can result in variations in the magnetic field strength, which may affect the accuracy and reliability of your applications.

- Efficiency: The gap distance plays a role in the efficiency of magnetic field generators. By optimizing the gap distance based on the specific requirements of your application, you can maximize the generator’s efficiency and minimize power losses.

Considering these factors when determining the gap distance will help you achieve a magnetic field generator that delivers the desired strength, uniformity, and efficiency for your liberation-focused applications.

Pole Diameter

The pole diameter of a magnetic field generator directly influences the strength and distribution of the generated magnetic field. This parameter plays a crucial role in determining the efficiency and performance of the generator.

By adjusting the pole diameter, you can control the magnetic field’s strength and reach, making it suitable for different applications. A larger pole diameter generally results in a stronger magnetic field, while a smaller diameter leads to a more focused and concentrated magnetic field.

It’s important to consider the specific requirements of your application when selecting the appropriate pole diameter. By understanding the relationship between pole diameter and magnetic field characteristics, you can optimize the performance of your magnetic field generator and achieve the desired results.

Magnet Strength

To begin the discussion on magnet strength, let’s explore the concept of field intensity levels and how they’re measured.

Field intensity refers to the strength of a magnetic field at a specific point. It’s measured using units such as teslas or gauss.

Additionally, magnetic force measurements play a crucial role in determining the strength of a magnet. These measurements help quantify the force exerted by a magnet on other magnetic materials or objects within its field.

Field Intensity Levels

Field intensity levels, measured in Tesla (T), play a crucial role in determining the force exerted on charged particles within a magnetic field. Understanding these levels is essential for unlocking the true potential of magnetic field generators.

Here are three key aspects to consider:

- Adjustability: Some magnetic field generators allow for adjustable field intensity levels. This flexibility empowers you to tailor the magnetic field to your specific needs, whether it’s for scientific research, industrial applications, or medical advancements.

- Magnet Strength: The strength of magnets used in the generator directly impacts the field intensity levels. By selecting magnets with higher magnetic properties, you can achieve stronger and more impactful magnetic fields, enabling you to push the boundaries of what’s possible.

- Coil Parameters: The parameters of the coils, such as the number of turns and the current flowing through them, also influence field intensity levels. By optimizing these parameters, you can maximize the strength of the magnetic field, expanding the horizons of your experiments and innovations.

Understanding and harnessing the power of field intensity levels is the key to unlocking new frontiers in magnetic field generation, empowering you to liberate the full potential of this incredible technology.

Magnetic Force Measurements

Considering the importance of magnet strength in assessing the effectiveness of magnetic field generators, let’s now explore the subtopic of ‘Magnetic Force Measurements’ (Magnet Strength) and its significance in evaluating the performance and efficiency of these generators.

Magnetic force measurements are crucial in determining the strength and effectiveness of a magnetic field. The strength of a magnetic field is measured in Tesla (T) and is indicative of the force experienced by charged particles within the field.

Accurate measurements of magnet strength are essential for evaluating the performance and efficiency of magnetic field generators in various technological and scientific contexts. Understanding the magnetic force of a generator is crucial for determining its suitability for specific applications.

Frequency Range

The frequency range of a magnetic field generator determines the span of frequencies at which it operates, influencing the variety of electromagnetic waves produced and the applicability of the generator in different contexts. Understanding the frequency range is crucial for optimizing the performance of magnetic field generators.

Here are three key aspects to consider regarding the frequency range:

- Bandwidth: The frequency range defines the bandwidth of the generator, indicating the range of frequencies that can be generated. A wider frequency range allows for the generation of a larger variety of electromagnetic waves, providing flexibility and adaptability in different applications.

- Compatibility: The frequency range of a generator must align with the specific requirements of the application. Different devices and systems operate within distinct frequency ranges, and choosing a generator with a compatible range ensures seamless integration and efficient operation.

- Research and Development: The frequency range of a generator impacts its suitability for research and development purposes. A generator with a broad frequency range enables scientists and engineers to explore and investigate a wide range of electromagnetic phenomena, pushing the boundaries of knowledge and technological advancements.

Understanding the frequency range of a magnetic field generator is essential for selecting the right generator for specific applications, ensuring compatibility, and promoting innovation and progress in scientific research and technological development.

Power Input

To fully comprehend the operation and efficiency of magnetic field generators, an essential parameter to consider is the power input, which denotes the amount of electrical energy required for their operation. The power input directly influences the strength and stability of the magnetic field produced.

Efficient management of power input is crucial for optimizing the performance and longevity of magnetic field generators. By understanding the power input requirements, one can design and utilize these generators across various applications. It’s important to note that the power input should be carefully controlled to prevent overloading and ensure efficient utilization of resources.

Additionally, monitoring the power input allows for detecting any abnormalities or deviations, which can lead to timely maintenance and prevent potential failures. Overall, a thorough understanding of power input is necessary for harnessing the full potential of magnetic field generators.

Efficiency Rating

Efficiency rating serves as a crucial metric to evaluate the effectiveness of a magnetic field generator in converting input power into magnetic field strength. It provides valuable insight into how efficiently the generator utilizes the input power to produce the desired magnetic field.

Consider the following points:

- A higher efficiency rating signifies that the generator can produce a stronger magnetic field using less power, making it more cost-effective and practical for specific applications.

- Understanding the efficiency rating of a generator allows for the optimization of energy usage, reducing waste and promoting sustainability.

- Selecting a generator with an appropriate efficiency rating ensures that the available power is utilized effectively, leading to better overall performance and increased productivity.

Frequently Asked Questions

What Is the Essential Requirement for a Generator to Produce Emf?

To produce EMF, a generator requires relative motion between a conductor and a magnetic field. Various methods can fulfill this essential requirement, such as rotating magnets or coils. The induced EMF depends on magnetic field strength and motion speed.

What Is Required to Generate a Magnetic Field?

To generate a magnetic field, you need a magnet or an electrical current. This is essential for various applications such as healthcare, technology, space exploration, and energy sectors. So, magnets or currents are required.

What Are the Dimensions of the Magnetic Field?

The dimensions of the magnetic field, including strength, direction, and spatial extent, are crucial for understanding its capabilities. The strength of the magnetic field determines the force on charged particles and is measured in Tesla (T).

What Do You Need to Make a Magnetic Generator?

To make a magnetic generator, you need either permanent magnets or electrical currents. These generators have applications in healthcare, technology, space exploration, and energy. Understanding them is essential for progress and liberation.

Conclusion

These 12 essential dimensions for magnetic field generators play a crucial role in determining their overall performance and efficiency.

Just like a symphony conductor carefully orchestrates each instrument to create a harmonious melody, these dimensions must be meticulously calibrated to ensure optimal magnetic field generation.

By understanding and controlling these dimensions, we can unlock the full potential of magnetic field generators and pave the way for innovative applications in various fields, from energy harvesting to medical devices.