Are you curious about the truth behind the theory that there are 9 best magnetic field generator designs? If so, you’re in the right place. These designs offer a range of benefits, from strong and homogeneous magnetic fields to scalability and adjustability.

But that’s not all. There’s more to discover about these innovative designs and how they can revolutionize various applications. So, keep on exploring to find out more about these fascinating magnetic field generator designs and their potential to shape the future.

Key Takeaways

- There are various types of magnetic field generator designs, including permanent magnet generators, electromagnetic generators, induction generators, and homopolar generators.

- Factors to consider in designing magnetic field generators include cost-effectiveness, energy efficiency, coil arrangement options, power output efficiency, and the advantages and limitations of different designs.

- Advanced technologies and materials, such as high-voltage pulsers, nested Halbach arrays, superconductors, and rare-earth magnets, can enhance the performance of magnetic field generators.

- Magnetic field generators have a wide range of applications, including wind turbines, electric vehicles, research fields, and industrial applications, and offer benefits such as compact design, high power density, reduced maintenance, enhanced efficiency, and longer lifespan.

Permanent Magnet Generator Design

Permanent magnet generator designs offer a cost-effective and energy-efficient solution for creating strong and uniform magnetic fields. These generators operate in an area with 3D mechanical and optical access, making them versatile and adaptable for various applications.

The magnetic fields generated by permanent magnet generator designs can reach several kilogauss, providing high amplitude outputs for diverse needs.

The scalability and adjustability of these generators in spatial dimensions enable the creation of different magnetic field topologies, making them suitable for a wide range of applications. Whether you need a strong and homogeneous magnetic field for scientific research, industrial processes, or medical imaging, permanent magnet generator designs have got you covered.

In an article published in AIP Advances by Oleg Tretiak, Peter Blümler, and Lykourgos Bougas, the potential and future prospects of these magnetic field generator designs are discussed. The authors highlight the low-cost and low-power consumption options offered by permanent magnet generator designs, making them an attractive choice for industries and research institutions alike.

With their ability to create strong and uniform magnetic fields, these generators provide an efficient solution for various applications. So, if you’re in need of a reliable magnetic field generator, look no further than permanent magnet generator designs.

Electromagnetic Generator Design

When considering electromagnetic generator design, it’s important to explore various factors that contribute to the creation of efficient and adaptable magnetic fields.

One key aspect to consider is the use of pulsed magnetic fields. Pulsed magnetic field generators offer several advantages over other designs. They’re capable of creating strong and homogeneous magnetic fields with low power consumption.

This makes them ideal for applications where efficiency is crucial. Additionally, pulsed magnetic field generators can be easily scaled and adapted to different requirements.

A promising approach in electromagnetic generator design is the use of nested Halbach arrays. These arrays allow for the creation of powerful and adjustable magnetic fields with 3D mechanical and optical access.

By arranging permanent magnets in a specific pattern, the Halbach array can effectively concentrate the magnetic field on one side while canceling it on the other.

This design enables the generation of highly controlled and directed magnetic fields, making it suitable for applications such as particle accelerators and magnetic resonance imaging (MRI) systems.

Recent research has also focused on high-voltage pulser design to generate even stronger magnetic fields. Advancements in this area have shown the potential to produce 30-T magnetic fields. Such capabilities open up new possibilities for scientific research, materials testing, and industrial applications.

Induction Generator Design

When designing an induction generator, you need to consider various coil arrangement options and their impact on power output efficiency.

The arrangement of the coils affects the strength and distribution of the magnetic field, which in turn influences the generator’s performance.

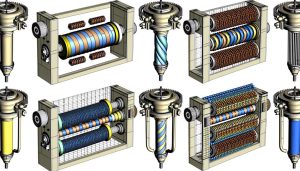

Coil Arrangement Options

Coil arrangement options in induction generator design play a critical role in determining the magnetic field strength and distribution patterns. Different coil configurations offer varying levels of efficiency and performance. By understanding and selecting the right coil arrangement, you can maximize the effectiveness of your induction generator.

To help you make an informed decision, here are some common coil arrangement options:

| Coil Arrangement | Advantages | Disadvantages |

|---|---|---|

| Concentric | Uniform field distribution | High manufacturing cost |

| Helical | Higher magnetic field strength | Complex construction |

| Radial | Efficient use of space | Uneven field distribution |

| Pancake | Compact design | Lower magnetic field strength |

| Axial | Easy cooling and maintenance | Limited scalability |

Each coil arrangement option has its own set of advantages and disadvantages, and the best choice depends on your specific application requirements and performance goals. By carefully considering these options, you can optimize the performance of your induction generator and achieve the desired magnetic field strength and distribution patterns.

Power Output Efficiency

To maximize the effectiveness of your induction generator, it’s crucial to optimize the power output efficiency through careful design considerations. Achieving high power output efficiency is essential for maximizing the electrical energy generated.

Here are three key factors to consider when designing an induction generator to enhance power output efficiency:

- Coil design: The design of the coils plays a significant role in power output efficiency. Using coils with a high number of turns increases the magnetic field strength, resulting in improved power generation.

- Magnetic field strength: The strength of the magnetic field generated by the induction generator affects the power output efficiency. Increasing the magnetic field strength through the use of powerful magnets or increasing the number of coils enhances power generation.

- Materials used: The choice of materials for the generator components can impact power output efficiency. Using materials with high magnetic permeability, such as iron or ferrite, can enhance the magnetic field and improve power generation.

Homopolar Generator Design

The simplicity and effectiveness of homopolar generator design make it a popular choice for specific industrial and research applications. Homopolar generators focus on generating electrical power through a simple, direct current (DC) generator.

This design typically consists of a rotating conductive disk, a magnetic field, and a current collection system. The table below provides a summary of the key components and features of homopolar generator design:

| Component | Description |

|---|---|

| Rotating Disk | A conductive disk that rotates in the presence of a magnetic field, creating a potential difference. |

| Magnetic Field | A magnetic field is created using permanent magnets or electromagnets to induce a current in the disk. |

| Current Collector | A system that collects the current produced by the rotating disk and transfers it to an external circuit. |

| High Current | Homopolar generators are capable of generating high current, making them suitable for specific applications requiring high power output. |

Homopolar generators are commonly used in research fields such as plasma physics and high-energy-density experiments, where high current is essential. The simplicity of the design allows for easy construction and maintenance, making it a cost-effective choice for industrial applications.

The direct current output of homopolar generators makes them suitable for powering devices that require a continuous and stable power supply. However, it is important to note that homopolar generators have limitations, such as lower voltage output compared to other generator designs.

Nonetheless, their unique characteristics and high current capabilities make them a valuable tool in various industrial and research settings.

Radial Flux Generator Design

Radial flux generator design maximizes magnetic field efficiency by directing the magnetic flux in a radial direction, allowing for a compact and high-efficiency generator suitable for various applications.

Here are three key features of radial flux generator design:

- Efficient utilization of magnetic materials: Radial flux generators are designed to optimize the use of magnetic materials, reducing wastage and maximizing the generation of magnetic fields. By focusing the magnetic flux in a radial direction, these generators can efficiently harness and utilize the magnetic properties of the materials, resulting in higher overall efficiency.

- Minimized magnetic losses: The radial flow of magnetic flux in these generators helps to minimize magnetic losses. By directing the flux in a radial path from the center to the periphery of the generator, the design reduces the chances of magnetic field leakage and energy dissipation. This results in improved efficiency and performance.

- Compact and lightweight design: Radial flux generators are known for their compact and lightweight design. By directing the magnetic flux radially, these generators can be constructed in a more compact manner compared to other generator designs. This makes them suitable for applications where space and weight constraints are crucial, such as in wind turbines and electric vehicles.

Axial Flux Generator Design

When it comes to axial flux generator design, efficiency is a key factor to consider.

Axial flux generators offer advantages such as high power density, compactness, and improved heat dissipation. However, they also have limitations, including complexity in design and manufacturing.

Understanding the efficiency and both the advantages and limitations of axial flux generators is crucial for optimizing their performance in various power generation applications.

Efficiency of Axial Flux

Axial flux generators exhibit exceptional efficiency in converting mechanical energy to electrical energy, making them an ideal choice for various applications. The efficiency of axial flux generators can be attributed to several key factors:

- Compact and lightweight design: Axial flux generators are designed to be more compact and lightweight compared to traditional radial flux generators. This design feature reduces energy losses and increases overall efficiency.

- Shorter magnetic flux path: The unique configuration of axial flux generators allows for a shorter magnetic flux path. This design minimizes energy losses and improves the efficiency of energy conversion.

- Effective cooling and heat dissipation: The axial flux generator design enables efficient cooling and heat dissipation. This feature helps maintain optimal operating temperatures, enhancing overall performance and efficiency.

Advantages and Limitations

The advantages and limitations of the axial flux generator design can greatly impact its suitability for various applications. One advantage of this design is its efficient power generation, thanks to the shorter flux path and high power density.

Axial flux generators are also lighter and more compact than radial flux generators, making them ideal for applications where space and weight are critical considerations.

Additionally, they offer improved cooling capabilities and better thermal performance compared to radial flux generators, potentially leading to longer lifespans. These generators can be easily integrated into systems with low rotational speeds, making them suitable for wind turbines and certain industrial applications.

However, there are limitations to consider, such as potential challenges in achieving high torque and difficulties in scaling the design for larger power outputs.

| Advantages | Limitations |

|---|---|

| Efficient power generation | Challenges in achieving high torque |

| Compact and lightweight | Difficulties in scaling for larger power outputs |

| Improved cooling capabilities | – |

Brushless Generator Design

To enhance efficiency and reliability, brushless generator design eliminates the need for brushes and commutators. This design change has several advantages:

- Reduced Maintenance: The absence of brushes and commutators means there are fewer parts that can wear out or require regular maintenance. This leads to a longer lifespan for the generator and reduces the need for costly repairs or replacements.

- Enhanced Efficiency: Brushless generators utilize electronic controllers to regulate the flow of current. This allows for precise control over power generation, resulting in higher efficiency and optimized power output. The magnetic field generated by the generator is more stable and consistent, leading to improved overall performance.

- Smoother Operation: Compared to traditional brushed generators, brushless generators offer smoother operation and reduced noise levels. The elimination of brushes and commutators eliminates the mechanical friction and sparking that can cause vibrations and noise. This makes brushless generators ideal for applications where quiet operation is desired.

Hybrid Generator Design

Hybrid generator design combines permanent magnets and electromagnets to create a powerful and adjustable magnetic field, offering a versatile solution for a wide range of applications.

This design allows for the creation of strong and homogeneous magnetic fields with low power consumption. It offers the flexibility to adjust spatial dimensions and generate various magnetic field topologies.

The hybrid generator design is suitable for a wide range of applications and can be utilized for table-top scientific experiments. Researchers are exploring novel potential applications and optimizing the design for enhanced performance.

| Advantages | Disadvantages |

|---|---|

| – Powerful and adjustable magnetic field | – Requires a power source for the electromagnets |

| – Low power consumption | – Complex design and manufacturing process |

| – Flexibility to adjust spatial dimensions | – Higher initial cost compared to other designs |

| – Capable of generating various magnetic field topologies | – Requires maintenance and periodic calibration |

| – Versatile solution for a wide range of applications | – Limited scalability for large-scale applications |

The hybrid generator design combines the best features of permanent magnets and electromagnets, offering a balance between power and adjustability. The permanent magnets provide a stable and consistent magnetic field, while the electromagnets allow for fine-tuning and adjustment of the field.

This design is particularly useful in scientific experiments where precise control over the magnetic field is required. Additionally, the low power consumption of the hybrid design makes it an energy-efficient choice.

However, the complexity of the design and the need for a power source for the electromagnets can pose challenges. Despite these drawbacks, ongoing research and development aim to overcome these limitations and optimize the hybrid generator design for improved performance.

High-Efficiency Generator Design

Building upon the advancements in hybrid generator design, the subtopic of high-efficiency generator design focuses on maximizing energy conversion and minimizing energy loss through the utilization of advanced materials and technologies. In order to achieve high efficiency, there are several key considerations that must be taken into account:

- Advanced Materials: High-efficiency generator designs incorporate advanced materials that have superior electrical conductivity and magnetic properties. These materials, such as superconductors and rare-earth magnets, minimize energy loss and maximize power output.

- Innovative Technologies: Cutting-edge technologies, such as power electronics and digital control systems, are employed in high-efficiency generator designs. These technologies optimize the performance of the generator by reducing losses and improving the overall energy conversion efficiency.

- Optimal Design Considerations: High-efficiency generator designs prioritize factors like heat dissipation and power output. By carefully considering these design aspects, engineers can minimize losses due to heat and maximize the overall efficiency of the generator.

Conclusion

These 9 magnetic field generator designs offer a range of benefits including strong and homogeneous magnetic fields, scalability, low-cost and low-power consumption, and compatibility with various applications.

They represent innovative approaches to generating stronger magnetic fields and exploring novel applications. Like a symphony conductor, these designs harmoniously orchestrate magnetic fields, allowing for versatile and adaptable performance.

With their efficiency and versatility, they have the potential to revolutionize magnetic field generation in various industries.