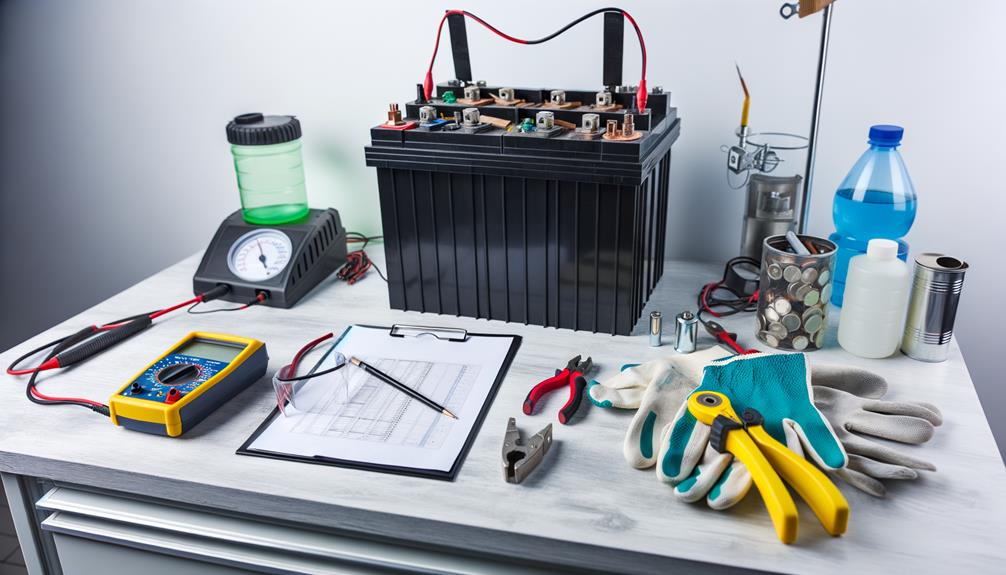

In the domain of sustainability and cost-efficiency, a lead acid battery reconditioning stands out as a prudent choice. The process begins with a thorough assessment of the battery’s current state, employing tools such as a multimeter and hydrometer to guarantee precise measurements of voltage and specific gravity.

Upon establishing a baseline, the focus shifts to meticulous charging protocols tailored to rejuvenate neglected cells without causing undue strain. Yet, the true measure of success in this endeavor hinges on the third step, which not only confirms the efficacy of the prior actions but also reveals the battery’s potential for reliable, extended use. Discovering what this critical final evaluation entails could fundamentally alter your approach to battery maintenance.

Key Takeaways

- Assess the battery condition using a multimeter and hydrometer to check voltage and specific gravity.

- Implement proper charging techniques, using slow or pulse charging to restore battery cells.

- Regularly perform equalization charges to balance cell voltages and prevent sulfation.

- Conduct discharge tests to evaluate battery health and efficiency after reconditioning.

- Inspect visually for signs of damage like sulfation and electrolyte leakage, and address as needed.

Assess Battery Condition

To effectively assess the condition of a lead acid battery, begin by using a multimeter to measure its voltage; readings below 12 volts usually indicate a discharged or potentially defunct battery. This initial step is essential for determining whether the battery can still function or if it requires reconditioning or replacement.

Further, conducting a capacity test is important to ascertain the actual milliampere-hour (mAh) capacity remaining in the battery. This involves discharging the battery at a controlled rate and comparing the outcome to its rated capacity. A significant decline in capacity is a clear indicator of battery deterioration.

Additionally, visual inspection can reveal much about a battery’s health. Key indicators such as sulfation — the accumulation of lead sulfate crystals on the plates — and signs of electrolyte leakage are significant to note. Both are symptoms of aging or internal damage. Understanding the importance and functionality of battery banks can further inform the necessity of these assessments.

For a more detailed analysis, employ a hydrometer to measure the specific gravity of the battery’s electrolyte. A specific gravity around 1.270 SG typically signifies a healthy battery. Conversely, deviations from this value can suggest dehydration or over-sulfation, warning of potential internal failures.

Through these diagnostic steps, one can reliably assess battery condition and decide the necessary corrective actions.

Implement Proper Charging

Once the condition of a lead acid battery is thoroughly assessed, the next essential step involves implementing proper charging techniques. Proper charging is not just about replenishing the battery’s power; it is a vital process that considerably impacts the longevity and performance of the lead acid battery.

Here are the key techniques to follow:

1. Utilize Slow Charging: Slow charging is important for reconditioning sulfated batteries. It allows for a gradual restoration of the battery cells, minimizing the risk of overheating and further damage. Aim to keep the charge current at no more than 10% of the battery’s rated amperage per hour to guarantee safety and effectiveness.

2. Employ Pulse Chargers: Pulse chargers, operating at around 1kHz, help to disintegrate the lead sulfate crystals that can form on the cells, which are often the main culprits behind decreased battery efficiency. This technique has shown promising results in restoring battery function and extending its usable life.

3. Monitor Charging Duration and Conduct Equalization Charges: Keep a close watch on the charging time; for example, a deeply discharged battery might need up to 48 hours for ideal voltage stabilization.

In addition, for maintaining battery health, perform equalization charges regularly—monthly for non-sulfated batteries and after every charging cycle for sulfated ones. This helps in balancing the battery cells and prolonging battery life.

Conduct Discharge Testing

Conducting a discharge test is a significant step in evaluating the health and efficiency of a lead acid battery after it has been charged. This procedure helps to determine the remaining capacity and overall functionality of the battery, thereby indicating whether it is in acceptable health or poor condition.

For instance, the first battery in our assessment overheated and exhibited a significant voltage drop during the discharge test, clearly signaling its degraded state. On the other hand, the second battery managed a discharge capacity of 6682mAh, confirming its good condition and efficient recovery.

To guarantee the reliability of these results, discharge tests must be performed under controlled conditions with a consistent load applied to the batteries. This standardization is essential for obtaining accurate and comparable data across various batteries.

Additionally, it is critical to continuously monitor both voltage and temperature throughout the discharge process. These measurements provide important insights into the performance characteristics of lead acid batteries, helping to prevent potential damage from excessive strain or overheating during the test.

Regular monitoring is fundamental, as outlined in the battery maintenance tips, to enhance the operational longevity and efficiency of lead acid batteries. By adhering to these guidelines, one can effectively assess and enhance the operational longevity of lead acid batteries.

Conclusion

Lead acid battery reconditioning comprises a systematic approach involving assessment, controlled charging, and discharge testing. By meticulously evaluating the battery’s condition through precise measurements and adhering to ideal charging protocols, the restoration process enhances the battery’s performance and longevity.

Regular discharge tests further validate the effectiveness of the reconditioning efforts, ensuring that the battery remains efficient and reliable for extended usage, thereby contributing to sustainable battery management practices. If you are interested in a detailed guide on lead-acid battery reconditioning, or any type of battery, please watch the following video and click the link now!