To set up a magnetic power generator effectively, avoid common mistakes such as poor wiring connections, which can result from debris or oxidation. Ascertain that all connections are secure and inspect circuit integrity using a multimeter to prevent functionality disruptions. Additionally, prioritize proper coil design; select appropriate magnetic materials to maintain operational efficiency and optimize coil orientation for enhanced voltage output.

Observe safety precautions, including grounding techniques and regular maintenance schedules to ascertain longevity. By focusing on these critical areas, you can enhance both performance and safety, illustrating the importance of meticulous attention to setup processes in generator operations.

Common Wiring Issues

When setting up a magnetic power generator, you need to be aware of common wiring issues that can considerably affect its performance. Poor connections due to inadequate cleaning of ports often lead to notable operational problems.

Confirm all connection points are free of debris, as any blockages can compromise efficiency. Additionally, maintaining soil health through effective fertility management can greatly influence overall system performance.

In addition, loose connections must be addressed; tight connections enhance reliability under continual operation. Keep an eye out for oxidation, as surface oxide layers reduce electrical contact, necessitating that you polish these surfaces regularly.

Identifying wiring errors promptly is essential for uninterrupted functionality, while regular checks can help avert connection-related complications. If you’re facing tripped breakers, determine and rectify the underlying cause before restarting the generator.

Verify circuit integrity through the use of a multimeter to detect any blockages and verify that the excitation circuits are reconnected correctly. Moreover, maintain proper usage guidelines to prevent issues like backfeeding the grid or improper load management, as these can lead to dangerous situations. Additionally, consistent monitoring of clean connections not only enhances efficiency but also minimizes risks associated with power loss.

⚡OFF-GRID POWER⚡

Build a Home Power Backup—No Utility Needed

Looking to keep essentials running during outages? The Ultimate Off-Grid Generator course walks you through a DIY backup system with simple parts and step-by-step plans — ideal for homesteads, cabins, or emergency prep.

Magnetic Field Considerations

Understanding magnetic field factors is essential for optimizing the performance of your magnetic power generator. The efficiency of your generator largely hinges on understanding field strength and the induction principles that govern electromagnetic interactions. It’s important to recognize that field strength notably influences the output; as you adjust the current pulse shape, you’ll notice varying effects on energy generation.

When selecting magnetic materials, verify that they operate well below saturation levels, as saturation can lead to considerable losses, diminishing the operational effectiveness of your generator.

Minimizing switching and conduction losses is critical; you should prioritize devices specifically designed for low-loss operation. Additionally, classifying MFGs by their characteristics can help in identifying the most suitable design for your specific application. Furthermore, magnet-powered generators offer reduced maintenance costs owing to fewer moving parts.

Additionally, be mindful of the angular orientation of the magnetic field lines relative to your coils, since this angle directly impacts current generation. The movement between the magnetic field and the coil is integral to producing electricity, necessitating careful design to facilitate this relative motion.

Furthermore, focusing on the rate of change in magnetic field strength can greatly enhance your system’s efficiency. By adhering to these magnetic field considerations, you can foster a robust setup that maximizes your magnetic power generator’s potential, ultimately leading to a more efficient energy solution.

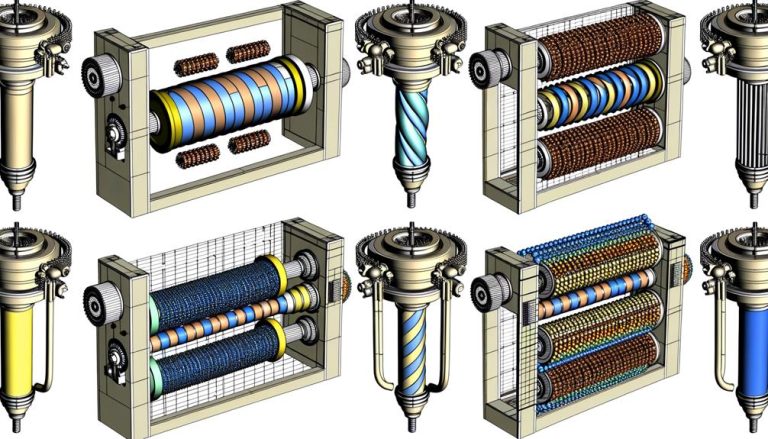

Coil Design and Construction

Coil design and construction play an essential role in the effectiveness of your magnetic power generator. To maximize performance, consider wire size, as it greatly influences efficiency and power output. You’ll also need to pay careful attention to coil orientation and guarantee that the placement of magnets relative to the coil is ideal for generating electricity.

For a robust coil, don’t overlook epoxy application; securely applying epoxy during the winding process not only maintains the coil’s shape but also prevents unwinding over time. Applying epoxy at key locations during winding provides vital support and strength to your coils. Additionally, be aware that proper insulation methods can protect your equipment from potential hazards during operation.

When winding the coil, use pre-measured wire to achieve consistent sizes, and employ a simple setup, such as lag bolts, for efficient winding. After completing the winding, tighten the coil using a screw or clamp to maintain form.

Additionally, consider the number of turns; more turns typically yield a higher voltage output. Proper insulation, such as snow seal or car wax, is vital to prevent the epoxy from sticking during this meticulous process.

Remember that incorporating these factors effectively can enhance your generator’s overall efficiency, allowing you to achieve your electrical generation goals with confidence and precision.

Safety Precautions

Safety precautions are critical when setting up a magnetic power generator. You must familiarize yourself with all safety guidelines that pertain to the equipment, as failure to observe warning signs or instructions can lead to serious injuries or even fatalities.

It’s essential that you thoroughly read the user manual before proceeding with the setup, ensuring you understand the associated safety information, which will guide your actions accordingly. Regular inspections are also advisable to catch any potential hazards early on.

Make sure to employ proper electrical insulation techniques to protect yourself from potential electrical hazards during the installation process. Always use grounded extension cords to connect appliances directly to the generator, and never link the generator directly to your home’s electrical system without a certified transfer switch. Additionally, proper maintenance of the PMG is vital for its efficiency and overall performance.

Additionally, secure grounding connections to prevent electrical shocks and conduct regular inspections of extension cords to identify any damage that could exacerbate hazards. Regular checks for pests can help ensure a safer environment when working near the generator, as pests may create unexpected risks.

When working near the generator, wear protective gloves, and keep your hands and loose clothing clear of moving parts, as these can pose significant risks.

Troubleshooting and Maintenance

When tackling troubleshooting and maintenance for your magnetic power generator, it’s crucial to recognize common issues that can disrupt its performance. One key problem is the loss of residual magnetism, often caused by infrequent usage, running without a load, or improper shutdown procedures.

If you encounter this, a simple method to restore it involves flashing the generator with a 12-volt battery. Additionally, it’s essential to maintain an optimal configuration, similar to how micro inverters optimize panel performance, to prevent underperformance issues.

Additionally, verify you regularly check and tighten connections, as poor connections can impede electricity production. To optimize your generator efficiency, establish a maintenance schedule that includes monthly operation, cleaning oil and air filters, and testing batteries.

Regular generator maintenance can prevent decreased performance and potential damage. Always be cautious with fuel quality; substandard or old fuel can clog injectors and diminish output.

When troubleshooting, utilize diagnostic tools such as a multimeter to identify circuit wiring errors or blockages, and inspect for tripped breakers before restarting. Furthermore, keep an eye on worn brushes and defective capacitors, as these components can greatly impact overall functionality. Regular maintenance and prompt troubleshooting not only enhance your generator’s lifespan but also foster a reliable power source you can trust.

⚡OFF-GRID POWER⚡

Build a Home Power Backup—No Utility Needed

Looking to keep essentials running during outages? The Ultimate Off-Grid Generator course walks you through a DIY backup system with simple parts and step-by-step plans — ideal for homesteads, cabins, or emergency prep.

Frequently Asked Questions

How Do I Estimate the Efficiency of My Magnetic Power Generator?

To estimate the efficiency of your magnetic power generator, begin with a performance analysis that compares output power to input power.

Calculate total losses, including core and eddy current losses, then apply the formula: Efficiency = (Output Power – Total Losses) / Input Power.

Verify you assess factors such as magnetic field strength and rotor speed, as they directly influence your efficiency estimation, thereby enhancing the overall performance of your generator.

Can I Use Recycled Materials for Building My Generator?

Absolutely, you can use recycled materials for generator construction. Utilizing items such as recycled copper wire and repurposed magnets enhances sustainability, but make certain these materials meet specific quality standards.

Cleanliness, compatibility, and durability are essential; old machinery parts and plastic components can be useful if appropriately chosen.

Start with a simple prototype to understand operational fundamentals, and remember to prioritize insulation and safety in your design to facilitate efficient electricity generation.

What Is the Best Way to Test for Generator Performance?

To effectively test your generator performance, establish clear performance benchmarks that reflect your objectives.

Utilize various testing methods, such as measuring magnetic field strength with appropriate coils, and conducting efficiency assessments through load testing.

Employ transient generators to simulate real-world conditions, and analyze the collected data systematically to inform your design improvements.

How Often Should I Perform Maintenance on My Generator?

To maximize your generator’s lifespan, establish a thorough maintenance schedule. Conduct monthly inspections, evaluating components for wear and tear, including calibration checks to guarantee peak performance.

Implement quarterly maintenance, which should involve thorough cleaning and alignment checks, while performing an annual overhaul to identify and rectify latent issues.

Document all maintenance activities, allowing for a clearer understanding of the generator’s condition and guiding future maintenance decisions effectively.

Consistency is key to longevity.

What Are the Environmental Impacts of Using Magnetic Generators?

When considering the environmental impacts of using magnetic generators, you should note that the magnetic field’s strength directly influences energy output.

Suboptimal configurations can lead to increased energy consumption and resource strain, particularly in sourcing the magnetic materials.

In addition, the manufacturing processes for these components may involve hazardous chemicals and generate waste, thereby exacerbating pollution and ecological degradation if not managed responsibly.

As a result, evaluating sustainability practices is essential for minimizing ecological footprints.

Conclusion

To conclude, by diligently addressing common pitfalls such as wiring inconsistencies, magnetic field miscalculations, and inadequate coil design, you can enhance the efficiency and safety of your magnetic power generator. Furthermore, adhering to strict safety precautions and implementing a robust troubleshooting and maintenance regimen will not only prolong the lifespan of your generator but also maximize its performance. By avoiding these mistakes, you’re ensuring a more successful and rewarding experience in harnessing the potential of magnetic energy.