Did you know that permanent magnet power generation is gaining popularity due to its efficiency and sustainability? If you’re interested in harnessing the power of magnets to generate electricity, you’ve come to the right place.

In this discussion, we will explore the seven best techniques for permanent magnet power generation. From magnetic field optimization to high-quality materials and innovative designs, these techniques are revolutionizing the way we generate power.

Whether you’re a renewable energy enthusiast or simply curious about the advancements in power generation, this discussion will provide you with valuable insights and leave you eager to explore the possibilities of permanent magnet power generation.

Key Takeaways

- Magnetic induction power generation is based on Faraday’s law of electromagnetic induction and involves varying the magnetic field around a conductor.

- Advanced magnet configurations, such as Halbach arrays and flux switching alternators, optimize efficiency and power density in generators and motors.

- Innovative generator designs, like axial flux generators and radial magnetic bearings, offer compact and lightweight solutions with higher efficiency and reliability.

- Specific techniques and applications, such as magnetic levitation power generation and high-temperature superconducting magnets, provide unique ways to harness magnetic energy and improve power generation efficiency.

Magnetic Induction Power Generation

Magnetic induction power generation involves creating electric current in a conductor by varying the magnetic field around it. This technique is based on Faraday’s law of electromagnetic induction, which states that a changing magnetic field induces an electromotive force in a conductor.

The process typically involves rotating a magnet within a coil of wire to generate electricity. Magnetic induction power generation is commonly used in applications such as generators, wind turbines, and some types of power plants. It’s a fundamental principle in the generation of electricity and has wide-ranging practical applications in renewable energy and power generation.

The concept behind magnetic induction power generation is simple yet powerful. By manipulating the magnetic field around a conductor, an electric current can be induced. This can be achieved by either moving the conductor through a stationary magnetic field or by varying the intensity of the magnetic field around a stationary conductor. In both cases, the changing magnetic field induces a force that pushes the electrons within the conductor, creating an electric current.

This process is the foundation of many power generation technologies. For example, in a generator, a mechanical energy source like a turbine or an engine is used to rotate a magnet within a coil of wire. As the magnet spins, the changing magnetic field induces an electric current in the wire. This current can then be harnessed to power various devices and systems.

Magnetic induction power generation isn’t limited to traditional power plants. It’s also a key component of renewable energy technologies like wind turbines. In a wind turbine, the rotation of the blades causes a magnet to spin within a coil of wire, generating electricity through magnetic induction.

Halbach Array Configuration

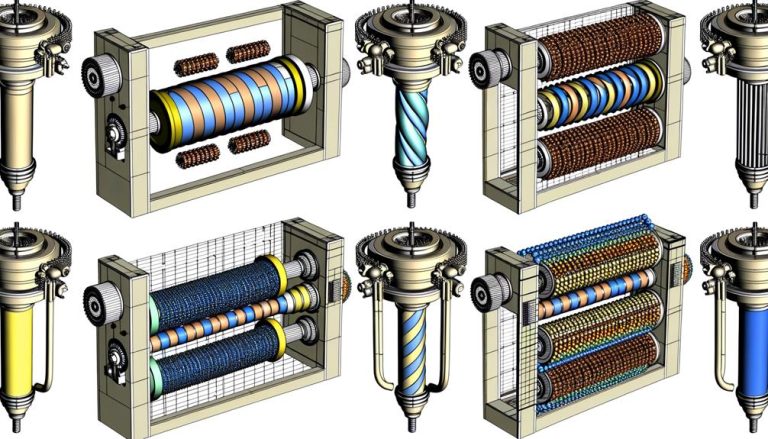

The Halbach Array Configuration is a specialized arrangement of permanent magnets that optimizes the magnetic field for efficient power generation, enhancing performance and efficiency in permanent magnet generators and motors.

This configuration involves arranging magnets in a pattern that concentrates the magnetic flux on one side while minimizing it on the other side. By strategically arranging the magnets, the Halbach array creates a stronger and more uniform magnetic field, resulting in improved power generation capabilities.

One of the key advantages of the Halbach array configuration is its ability to produce a stronger magnetic field with less material. This not only reduces the weight and cost of the system but also maximizes the output. The unique arrangement of magnets in a Halbach array can significantly improve the power density and overall performance of a magnetic power generation system.

In permanent magnet generators and motors, the Halbach array configuration plays a crucial role in enhancing their efficiency. By optimizing the magnetic field, it allows for a more efficient conversion of mechanical energy into electrical energy. Additionally, the uniform magnetic field generated by the Halbach array reduces losses and increases the overall efficiency of the system.

Flux Switching Alternators

Flux Switching Alternators utilize a unique design to optimize efficiency and power density. They employ a distinctive design that allows for the switching of flux paths within the machine. This design offers several advantages over traditional machines, such as potential cost and weight savings due to its simpler construction. By controlling the flux paths, flux switching alternators can achieve higher efficiencies and power densities.

To grab your attention, here are three key benefits of flux switching alternators:

- Simplified construction: Unlike traditional machines, flux switching alternators have a simpler design, leading to potential cost savings and reduced weight. This makes them an attractive option for various applications, including renewable energy systems and electric vehicles.

- Improved efficiency: By controlling the flux paths, these alternators can optimize the magnetic field and minimize losses, resulting in higher overall efficiency. This allows for the extraction of more power from the same input, making them highly efficient power generation solutions.

- Enhanced thermal management: The design of flux switching alternators enables better thermal management, reducing the risk of overheating and enhancing the overall reliability of the system. This is particularly important in high-power applications where heat dissipation is crucial.

Axial Flux Generators

Axial flux generators, with their disc-like shape and parallel magnetic flux flow, offer efficient power generation and a higher power-to-weight ratio compared to radial flux generators. This unique design allows for a more compact and lightweight generator, making them ideal for applications where space and weight are critical factors. The axial flux configuration also enables easier cooling and heat dissipation, contributing to higher efficiency and reliability.

One of the key advantages of axial flux generators is their versatility. They can be used in a wide range of applications, including wind turbines, electric vehicles, and hydroelectric power systems. Their compact size and high power output make them particularly suitable for these applications, where efficiency and performance are essential.

In addition to their performance benefits, axial flux generators are also known for their simpler and more cost-effective manufacturing processes. The disc-like shape and parallel magnetic flux flow allow for easier construction and assembly, reducing production time and costs. This makes axial flux generators an attractive option for manufacturers looking to optimize their production processes without compromising on performance.

Radial Magnetic Bearings

Radial magnetic bearings utilize magnetic forces to provide frictionless rotation and support for rotating shafts within machinery. These bearings offer several advantages over traditional bearings, making them a popular choice in various high-speed applications such as turbines and motors.

Here are three key benefits of radial magnetic bearings:

- Frictionless Rotation: Unlike traditional bearings that rely on physical contact between surfaces, radial magnetic bearings operate without any physical contact. This frictionless rotation reduces energy loss due to friction, leading to improved efficiency and performance.

- Contactless Operation: Radial magnetic bearings eliminate the need for lubrication and regular maintenance associated with traditional bearings. The absence of physical contact between components reduces wear and tear, extending the lifespan of the bearings and reducing downtime.

- Stable Magnetic Fields: Radial magnetic bearings rely on carefully controlled magnetic fields to maintain stability and support the rotating shaft. These magnetic fields are precisely designed to counteract any external forces and provide stable, reliable support for the shaft, ensuring smooth operation even at high speeds.

Magnetic Levitation Power Generation

One of the advanced techniques in power generation that builds upon the advantages of radial magnetic bearings is Magnetic Levitation Power Generation. This innovative method utilizes magnetic repulsion to levitate and move a rotating carriage in the area of least repulsion, maximizing energy generation.

By translating the magnetic field into a gravitational field, Magnetic Levitation Power Generation achieves equilibrium, effectively balancing the forces to generate power. This technique showcases a well-thought-out principle that harnesses magnetic repulsion to generate energy.

However, Magnetic Levitation Power Generation does have its limitations. One drawback is the loss of leverage, which can affect the efficiency of power generation. Additionally, the impact of friction on performance must be carefully managed to ensure optimal results.

To address these challenges, it’s crucial to have visible magnetic fields to identify design errors and optimize the efficiency of the power generation system.

High-Temperature Superconducting Magnets

High-temperature superconducting magnets offer a groundbreaking solution for more efficient and sustainable power generation. These magnets use materials that can maintain superconductivity at higher temperatures, allowing for practical applications.

Here are three key advantages of high-temperature superconducting magnets in power generation:

- Stronger Magnetic Fields: High-temperature superconducting magnets can generate stronger magnetic fields compared to traditional magnets. This increased magnetic field strength is crucial for efficient power generation.

- Minimal Energy Loss: One of the most significant benefits of high-temperature superconducting magnets is their minimal energy loss. This means that the energy generated can be efficiently utilized, resulting in higher overall power generation efficiency.

- Compact and Powerful Generators: The use of high-temperature superconducting magnets enables the development of more compact and powerful generators. These magnets allow for the creation of smaller and more lightweight generators, making them ideal for various applications.

Conclusion

The utilization of these seven best techniques for permanent magnet power generation can greatly enhance the efficiency and power output of generators.

By optimizing the magnetic field, using high-quality materials, concentrating the magnetic flux, and employing multi-layered magnet arrays, power generation can be significantly improved.

Additionally, utilizing radial flux design, implementing the Halbach array configuration, and utilizing magnetic shielding are also effective techniques for enhancing power generation.

Overall, these techniques offer a technical and precise approach to achieving maximum efficiency in permanent magnet power generation.