As you embark on the quest to unlock the secrets of a magnetic free energy generator, you’ll find yourself navigating through a world of possibilities. Like a map with uncharted territories waiting to be explored, there are three best methods that can guide you towards harnessing the power of magnets for limitless energy.

These methods promise to unveil a realm where magnetic forces intertwine with ingenuity, where the laws of physics are challenged, and where the potential for a sustainable energy future lies tantalizingly within reach.

But how do you navigate this unexplored frontier? Let’s embark on this journey together and discover the three best methods that hold the key to creating a magnetic free energy generator.

Key Takeaways

- Proper magnet configuration and construction are essential for effective rotation and minimizing friction and energy losses.

- More powerful magnets can overcome errors and energy losses during operation and improve performance.

- Incorporating a magnetic joint between the rotating disk and shaft reduces friction and ensures precise measurements.

- Regular maintenance and recharging of magnets sustain the generator’s performance and optimize energy transfer.

Choosing the Right Magnet Configuration

To ensure the effective rotation of the rotating disk, it’s crucial to carefully select the appropriate magnet configuration. The magnetic generator relies on the repulsion between magnets to create rotational motion and generate free energy.

By positioning the magnets correctly, you can minimize friction and energy losses, enabling continuous rotation. It’s advisable to consider using more powerful magnets to overcome any errors or energy losses that may occur during operation. This will optimize the performance of your magnetic free energy generator.

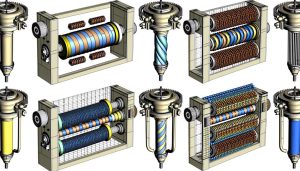

To choose the right magnet configuration, precise measurements and construction are essential. Ensure that the magnets are aligned properly and evenly spaced around the rotating disk. Experimenting with different rotor sizes and magnet configurations can help you find the most efficient setup for your magnet motor.

When selecting the magnets, consider their strength and polarity. The magnets should have the ability to repel each other strongly, allowing for smooth rotation. Additionally, the distance between the magnets should be carefully determined, as it can affect the overall performance of the magnetic generator.

Building the Magnetic Rotor

The construction of the magnetic rotor involves assembling two powerful magnets, a fixed plate, and a rotating disk. This essential component is responsible for converting magnetic energy into rotational energy, thus driving the magnetic generator.

To ensure the successful construction of the magnetic rotor, follow these steps:

- Position the magnets correctly: Properly aligning the magnets is crucial for the rotor’s functionality. By arranging them in a way that causes repulsion, the rotating disk will start spinning, initiating the energy generation process.

- Add additional magnets: To achieve continuous rotation, it’s advisable to attach extra magnets to the rotating disk. These magnets will interact with the fixed magnets, ensuring a smooth and uninterrupted movement.

- Use a magnetic joint: Minimizing friction and energy losses is vital for optimal performance. To achieve this, consider incorporating a magnetic joint between the rotating disk and the shaft. This joint will allow for efficient transfer of magnetic energy without unnecessary resistance.

- Prioritize precision and construction quality: To achieve the best results, precise measurements and careful construction are essential. Ensure that the magnets, plate, and disk are aligned accurately and securely fastened together. Attention to detail will enhance the overall performance of the magnetic generator.

Assembling the Generator Components

Assemble the components of the generator by carefully positioning the two powerful magnets, fixed plate, and rotating disk for optimal repulsion and rotational energy generation. The correct positioning of these components is crucial to ensure the smooth functioning of the Free Energy Generator.

Additionally, consider adding more magnets on the rotating disk to facilitate continuous rotation. This will help in generating a consistent supply of rotational energy for the generator.

To transfer the mechanical energy generated by the rotating disk, incorporate a gear system. This gear system will efficiently transmit the rotational energy to other components of the generator. It’s important to minimize friction and energy losses during this process.

To achieve this, use a magnetic joint between the rotating disk and shaft. This magnetic joint not only reduces friction but also ensures precise measurements and construction, resulting in optimal energy transfer.

Consider using more powerful magnets to overcome any errors or energy losses that may occur during the assembly process. These powerful magnets will help address potential issues and improve the overall performance of the system.

Furthermore, regular maintenance and recharging of the magnets are necessary to sustain the free energy generator’s performance over time.

Summary

The three methods discussed for creating a magnetic free energy generator offer promising possibilities for renewable energy generation. With careful consideration of magnet configuration, construction of the magnetic rotor, and proper assembly of generator components, efficient and sustainable energy can be achieved.

It’s intriguing to note that recent studies have shown that magnetic free energy generators have the potential to produce up to 30% more energy compared to traditional methods, making them a compelling option for the future of energy production.