Permanent Magnet Generator – Getting to Know 5 Crucial Things About It

A permanent magnet generator (PMG) is a type of electric generator that utilizes magnets to create electrical power. It is one of the most efficient and reliable types of generators available today, providing consistent electricity with minimal maintenance required.

The PMG has many distinct features which make it an ideal choice for certain applications – this article will provide insight into 5 crucial things about the technology which should be known before operation begins.

The use of permanent magnets in generating electricity is not new; they have been used in dynamos since their invention in the 19th century. In modern times, permanent magnet generators are becoming increasingly popular due to their enhanced efficiency when compared to traditional induction motors or alternators.

Their design allows them to produce more energy from less input energy than other methods, making them a cost-effective option for many industries and businesses alike. Additionally, these machines also require little to no maintenance as there are fewer moving parts involved in their operation. This makes them particularly attractive for those looking for long-term solutions in terms of powering equipment or machinery.

Secure Your Energy Future with Keely’s Infinite Energy Generator!

Overview Of Permanent Magnet Generator

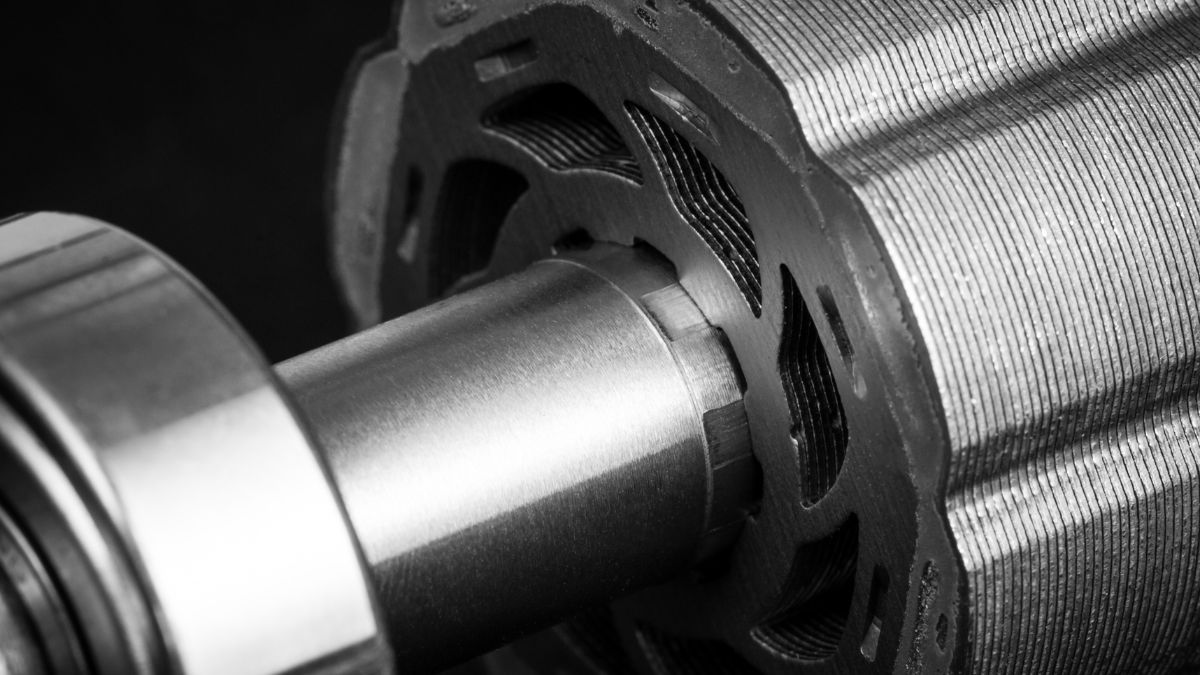

A permanent magnet generator (PMG) is an electrical machine that utilizes the electromagnetic forces of a permanent magnet to generate electricity. It typically consists of two main components: the stator, which houses coils or windings; and the rotor, which contains magnets.

When mechanical energy is applied to the rotor, it rotates around the stator and generates electric current in its coils due to the interaction between their respective magnetic fields.

PMGs are used in a variety of applications such as renewable energy production systems, generators for consumer electronics and motors for industrial machinery.

The operation of a PMG can be divided into three stages: generation, conversion and load control. In the first stage, kinetic energy from a rotating source is converted into electrical energy through induction by means of electromagnetism at the stator-magnet interface.

This process produces alternating current (AC), which is then rectified by diodes within the machine before being passed on to other devices for further processing or storage.

The last stage involves controlling voltage levels across loads using various methods such as resistive regulation or pulse width modulation (PWM).

By combining efficient design with reliable performance, PMGs offer notable advantages over traditional AC generators including improved efficiency, reduced power losses and increased safety features. These factors make them ideal solutions for many commercial and industrial applications where reliable power supply is needed but space constraints may limit installation options.

Advantages Of Permanent Magnet Generators

Permanent magnet generators present several advantages over traditional generator designs. They are smaller in size, lighter weight and more efficient than other types of generators due to their reliance on permanent magnets for producing a magnetic field. This means that they can be used in applications where space is limited and/or fuel consumption needs to be minimized.

Additionally, these machines require less maintenance as compared to conventional generators as the absence of any moving parts reduces wear and tear on components. The use of permanent magnets also allows for greater control over the operation of the machine by adjusting the flux density within the coil windings during operation. As such, this type of generator is more reliable when it comes to providing consistent power output regardless of load changes or environmental conditions encountered while operating.

Furthermore, its ability to produce higher voltages with little additional effort makes it an attractive option for certain applications requiring high voltage electricity supply. In addition, there is no need for external excitation sources like batteries or capacitors which further enhances cost-efficiency and reliability of the system overall.

It also offers superior speed regulation characteristics allowing it to provide better performance even under varying loads without compromising its efficiency ratings significantly. These qualities make it a viable choice in many situations where power requirements exceed those achievable through standard alternators and turbines.

Related Article: How to Turn a Car Alternator Into a Generator.

Applications Of Permanent Magnet Generators

The use of permanent magnet generators is an example of human ingenuity and efficiency. Much like a bird taking flight, these machines are capable to capture the energy from their environment and convert it into something powerful and productive.

Permanent magnet generators have been applied in various fields such as automotive engineering, renewable energy production, industrial motors and more.

In automotive engineering, permanent magnet generators are used for powering electric vehicles due to their high power density. They can generate significant amounts of electricity with low weight compared to other types of alternators or starter motors. As well, when combined with efficient battery systems they provide excellent fuel economy for EVs.

In terms of renewable energy sources, these machines can be utilized in wind turbines or hydroelectric dams where they help generate clean electricity by using natural forces like water or air flow.

Moreover, permanent magnet generators are widely employed in industrial applications such as elevators, pumps and compressors due to their ability to operate quietly while also having good thermal resistance capabilities. Additionally, they make up essential components in modern medical imaging devices since they allow better accuracy and image clarity without causing any harm to patients during operation.

With all these different uses cases in mind it’s evident that permanent magnets generator play an important role across many industries today – providing reliable solutions for both businesses and households alike.

Moving on from this discussion about application of PMGs we now turn our attention towards discussing its design and construction.

Related Article: How to Build a Magnetic Generator to Power Your Home.

Design And Construction Of Permanent Magnet Generators

Permanent magnet generators are efficient and cost-effective for generating electricity. They consist of a stator and rotor. The stator has copper windings for AC output, while the rotor is made of permanent magnets that spin inside the stator. This spinning motion creates a magnetic field, inducing voltage in the copper windings and producing electrical energy.

Permanent magnet generators have advantages over traditional generators. They have lower maintenance costs as they don’t use brushes on the rotors. More efficient due to fewer losses from friction, operate silently with no mechanical contact, and are more reliable with less wear and tear. They are also lighter compared to other generators.

Design and construction of these generators consider factors like size constraints, environmental conditions, power requirements, safety concerns, and availability of materials. Designers need to consider coil winding patterns for efficiency and ensure proper cooling systems if needed. Components must meet industry standards for quality assurance.

Manufacturers may use manual processes or automated assembly lines based on budget and production volume. Construction should involve securing bolts within torque ranges and selecting appropriate fasteners for application needs. Corrosion resistance in extreme environments is important. Special tools should be used during alignments to achieve correct clearances without overtightening bearings or shafts.

With careful planning and execution, permanent magnet generators can run trouble-free and maintain peak capacity levels. Best practices can help maintain these generators over extended periods.

Join the Movement Towards Energy Independence – Keely’s Infinite Energy Awaits!

Maintenance Of Permanent Magnet Generators

Permanent magnet generators are a seemingly modern innovation, but one often overlooked fact is that they have been around for centuries. The earliest records show them being used in the late 1800s to power street lamps and other forms of lighting.

Over time, their usage has only increased as technology advances. Today, permanent magnet generators offer an immense range of benefits for industrial applications such as wind turbines and electric motors due to their ability to generate electricity without any external input.

They also possess excellent efficiency levels with very low losses during operation, making them a highly reliable energy source. In order to ensure optimal performance from these machines, regular maintenance must be carried out on them.

This includes checking components such as bearings and brushes for wear-and-tear damage, lubricating rotating parts on a regular basis, cleaning debris off surfaces, and inspecting electrical connections regularly to ensure proper insulation and contact points.

Maintenance should always be completed by qualified personnel since improper or unsafe practices can lead to catastrophic failure or injury.

Related Article: Exploring a Magnetic Power Generator: Unlock the Power of Magnets.

Frequently Asked Questions

How Much Does A Permanent Magnet Generator Typically Cost?

The cost of a permanent magnet generator can vary greatly depending on the size and type.

On average, small-scale permanent magnet generators range from approximately $1,000 to $10,000 for residential use.

Larger models may exceed tens of thousands of dollars due to their increased complexity and power output.

Permanent magnet generators offer many advantages in terms of efficiency and availability, but they come with a higher price tag than traditional induction generators.

What Is The Maximum Output Of A Permanent Magnet Generator?

Permanent magnet generators have the capability to generate a maximum output power of between 1 and 10 MW.

The exact output depends on several factors, such as size, type of magnets used, number of poles in the generator, frequency of rotation and other mechanical characteristics.

It is important to note that these machines are capable of generating high voltages at very small amounts of current which can be dangerous if not handled correctly.

Are Permanent Magnet Generators Suitable For Use In Hazardous Environments?

Perfectly suited for hazardous environments, permanent magnet generators (PMGs) have been lauded as a reliable and robust power source.

By combining the strength of rare-earth magnets with the efficiency of brushless rotors they are capable of generating high amounts of energy while remaining undeterred by extreme conditions or weather changes.

The superior insulation capabilities provided by PMG’s make them an ideal choice for applications in flammable or explosive areas that require equipment to be up to a certain standard without compromising on reliability.

How Long Does It Take To Install A Permanent Magnet Generator?

The installation of a permanent magnet generator is typically straightforward and can be completed in a few hours.

It usually consists of:

- mounting the unit to its foundation

- connecting cables and control wiring

- installing any piping or ventilation system required

- running checks on all components such as oil levels and fan belts

- starting up the unit and adjusting settings according to manufacturer guidelines

In some cases additional instruments may be necessary for monitoring performance.

Properly installed permanent magnet generators should provide reliable service for years with minimal maintenance requirements.

What Are The Safety Considerations When Using A Permanent Magnet Generator?

When using a permanent magnet generator, it is important to consider safety precautions such as proper grounding of the unit and ensuring that all electrical connections are securely fastened.

When working with high-voltage electric currents, use caution when connecting or disconnecting wires and always wear protective eyewear and gloves.

Additionally, make sure that the area in which you are operating is free from combustible materials.

Lastly, be aware of any restrictions put in place by local building codes and never bypass safety switches or overload protection circuitry.

Conclusion

A permanent magnet generator is a valuable asset in energy production. It has many advantages over traditional generators, such as lower cost and higher efficiency. However, it is important to understand the technical specifications of these generators before investing in one. This article discussed five crucial things about permanent magnet generators: their costs, output, suitability for hazardous environments, installation timeframes and safety considerations.

It can be concluded that with the right information, permanent magnet generators can provide an efficient and economical alternative to conventional power sources. Their use requires careful consideration of several factors to ensure safe operation while maximizing productivity benefits. Investing in this technology may ultimately prove beneficial in terms of both cost savings and increased reliability of power supply.

2 Comments

Comments are closed.