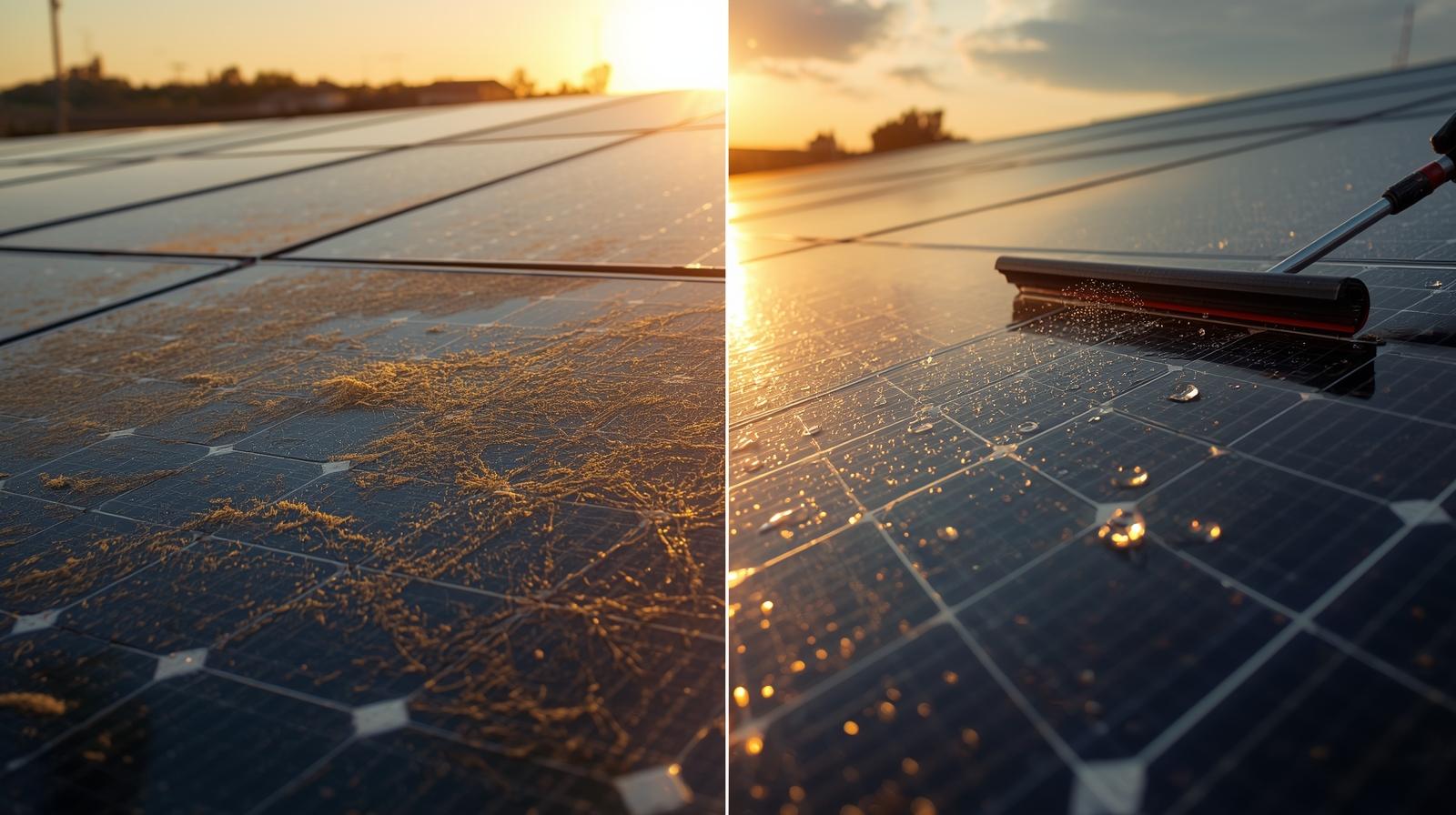

When you compare dry and wet solar panel cleaning, you should treat the choice like a controlled maintenance change in the IT/OT stack, governed by policy, metrics, and risk. Dry cleaning reduces electrical and corrosion risk but can leave abrasive particulates, while wet cleaning removes soiling yet consumes water and may leave mineral residue. You should baseline output, correlate with soiling and weather, and select a hybrid schedule, which the following sections describe in detail.

The Basics of Solar Panel Cleaning

Solar panel cleaning, when treated as a scheduled maintenance operation within a broader IT and OT (operational technology) governance framework, functions much like a deterministic maintenance job in a Kubernetes cluster, where you define clear triggers, constraints, and safeguards to minimize risk and maximize performance.

You first assess site-specific conditions, such as local dust levels, pollen, and industrial emissions, then set a solar panel maintenance policy that specifies cleaning frequency, approved cleaning tools, and access-control requirements for operators and contractors.

By monitoring generation metrics and correlating them with weather data and known dirt buildup, you can define thresholds that trigger cleaning tasks, while audit logs and change-control procedures guarantee traceability and compliance. During execution, you validate isolation of inverters, confirm adherence to safety checklists.

Advantages and Disadvantages of Dry Cleaning

Within the broader maintenance policy you’ve defined, dry cleaning methods—such as using antistatic brushes, microfiber pads, air blowers, or robotic wiper systems without introducing liquids—offer a distinct set of advantages and disadvantages that you must evaluate much like choosing a read-only maintenance job versus a state-changing operation in a Kubernetes cluster.

Using dry cleaning technology, you avoid moisture-driven corrosion, unmanaged chemical residues, and electrical safety risks, while still mitigating dust accumulation effects that degrade output.

You can schedule solar panel maintenance analogous to cron jobs, aligning cleaning frequency recommendations with local soiling rates, panel tilt, and environmental threats.

However, certain cleaning equipment options can abrade glass coatings, generate electrostatic discharge, or leave fine particulates, so you must define procedures, role-based access, and verification steps.

Advantages of Dry Cleaning

Properly engineered dry cleaning methods for photovoltaic arrays, when integrated into an automated monitoring and control stack analogous to a Kubernetes-managed workload, offer several operational advantages over wet cleaning, particularly in environments where water usage, chemical run‑off, or unplanned downtime must be tightly controlled.

When you design procedures to maximize dry cleaning efficiency, you can schedule jobs like cron-backed Kubernetes tasks, aligning dust removal techniques with irradiance forecasts, access windows, and security policies, thereby reducing maintenance frequency without degrading output.

Disadvantages of Dry Cleaning

Although dry cleaning workflows for photovoltaic arrays align well with automation-first, Kubernetes‑style orchestration, they introduce technical and operational drawbacks that you must account for in your maintenance architecture and security baseline.

Dry processes often reduce cleaning efficiency because brushes and air jets can’t fully dislodge caked debris, leading to persistent dust accumulation that degrades output and complicates performance monitoring.

Abrasive contact increases the risk of surface damage, which in turn expands your attack surface for moisture ingress and potential grounding faults. You must also schedule additional equipment maintenance for robots and actuators, consuming engineering time and spare parts.

While dry methods optimize water usage, they require stricter access control, safety interlocks, and audit logging to mitigate mechanical and insider threats during routine cluster-integrated operations.

Advantages and Disadvantages of Wet Cleaning

You don’t need to worry about damaging delicate parts or leaving streaks behind, with wet cleaning you can easily maintain your surfaces. By using water and a specialized cleaning solution, wet cleaning is an effective way to remove dirt that has accumulated on solar panels without risking scratches or other damage.

It’s important to be aware of the quality of the water used for this process since hard water can leave deposits that can reduce efficiency if left unchecked. Additionally, as with dry cleaning methods, it is important to use specialized cleaners designed specifically for solar panel surfaces in order to properly clean while also protecting their delicate parts and avoiding any harm from chemical compounds or solvents.

Wet cleaning offers several advantages over dry cleaning in terms of cost effectiveness because it is generally more efficient at removing dirt and debris than brushing or wiping with a cloth alone. This means less time spent on manual labor and therefore fewer costs associated with labor-intensive methods such as manual brushing or scrubbing.

Furthermore, utilizing special cleaners formulated for solar panel surfaces can help protect against potential damage while still achieving thorough results in a shorter period of time than what could be achieved manually. Ultimately, when considering cost effectiveness between wet and dry cleaning methods, it is important to weigh the pros and cons of both before making a decision about which approach best suits your needs.

Cost Comparison of Dry Cleaning Methods

Several cost dimensions emerge when you evaluate dry cleaning methods for solar panels, and you should model them with the same rigor you’d apply to sizing a Kubernetes cluster or hardening a security control. You first assess cost effectiveness by mapping each method to expected performance gains, then calculate per-panel and per-cycle costs based on projected cleaning frequency.

You quantify tool selection expenses, including brushes, microfiber systems, autonomous robots, and safety gear, and you amortize those over their service life. In parallel, you estimate labor expenses using time-per-array metrics, access constraints, and required skill levels.

Finally, you integrate these variables into a maintenance budgeting worksheet, iterating scenarios, validating assumptions against field data, and prioritizing methods that minimize lifetime levelized-cleaning cost across your entire portfolio.

Cost Comparison of Wet Cleaning Methods

Extending the same cost-modeling rigor you applied to dry cleaning, wet cleaning methods require you to quantify not only mechanical and labor inputs but also fluid consumption, wastewater handling, and chemical lifecycle overhead, all expressed in consistent per-panel and per-cycle units.

You treat wet cleaning materials as versioned artifacts, mapping procurement and storage costs similarly to container images in a Kubernetes registry. To structure a cost effectiveness analysis, you define:

- baseline water and detergent usage per panel, modeled as resource requests and limits;

- additional labor time per node, including harnessing and safety precautions;

- cleaning frequency impact, parameterized by soiling rates and regional weather effects;

- compliance-driven overhead for wastewater logging, encryption, and access control in your monitoring stack.

You then benchmark per-cycle cost baselines.

Factors to Consider When Choosing a Cleaning Method

When you choose a solar panel cleaning method, you need to evaluate it as you’d a Kubernetes workload profile, aligning mechanical processes, fluidics, and chemical agents with constraints on reliability, observability, and security across the entire lifecycle.

First, classify panel types and mounting architectures, since coatings, tilt, and electrical grounding influence which solvents, brushes, or dry tools are permissible without violating warranty or safety policies. Next, map expected dirt accumulation and local weather conditions, treating them as environment variables that drive cleaning frequency and method selection.

Then, assess accessibility issues, comparable to network reachability, determining whether automated systems, extension tools, or rope access are required. Finally, validate personnel authorization, data logging, and incident-response procedures for any outsourced cleaning provider against defined security policies. Additionally, understanding solar panel efficiency and performance impacts can help tailor cleaning schedules to optimize energy output and system longevity.

The Benefits of a Regular Cleaning Schedule

Although panel soiling might appear intermittent and workload-dependent, instituting a regular cleaning schedule functions much like defining a recurring maintenance job in Kubernetes that enforces predictable performance baselines.

This is because you standardize intervals for removing particulate buildup, organic residues, and mineral deposits, thereby stabilizing energy yield, reducing variance in system output, and simplifying capacity planning for downstream electrical loads.

By treating regular maintenance as a scheduled, version-controlled task, you can align cleaning frequency with telemetry thresholds, security policies, and warranty constraints.

- Document intervals, soiling levels, and escalation paths.

- Integrate inspections with alerts for performance optimization.

- Use checklists that verify sensor integrity and surface conditions, ensuring an efficiency boost.

- Review logs, correlating cleaning events with output metrics, rates, and long term savings.

The Environmental Impact of Cleaning Solar Panels

Because cleaning solar panels introduces additional water usage, chemical exposure, and energy consumption into the operational lifecycle, you need to evaluate the environmental impact with the same rigor you’d apply to defining resource requests, security contexts, and network policies in a Kubernetes cluster, explicitly quantifying inputs, outputs, and associated risks.

You should model water usage as a bounded resource, applying water conservation strategies and logging volumes, sources, and discharge locations. For detergents and coatings, you must verify safety data, prioritize eco friendly products, and track chemical inventories.

To maintain compliance with solar energy regulations, you need to document how your procedures reduce the environmental footprint, define measurable sustainability practices, and review them through structured audits and maintenance runbooks, updated, versioned, and approved by stakeholders.

Common Mistakes to Avoid When Cleaning Solar Panels

Effective environmental controls and compliance baselines for solar panel maintenance only provide value if you also avoid operational errors that increase risk, so you need to treat cleaning procedures the way you’d treat production cluster changes, identifying and eliminating common misconfigurations before execution. When defining cleaning frequency, you must document repeatable runbooks, align them with site-specific weather conditions, and avoid ad-hoc decisions.

- Validate cleaning materials against module manufacturer specifications, rejecting abrasive pads, strong solvents, or unvetted detergents.

- Enforce safety measures comparable to datacenter work-at-height policies, including lockout procedures and PPE.

- Prohibit high-pressure water and untested cleaning techniques that can compromise seals or anti-reflective coatings.

- Disallow cleaning during extreme temperature swings or high irradiance, which can induce thermal shock and re-soiling.

Professional Vs DIY Solar Panel Cleaning

When you evaluate professional versus DIY solar panel cleaning, you should assess them with the same rigor you’d apply to managing a Kubernetes cluster, considering standardized procedures, access controls, and operational risk.

Professional services typically provide structured maintenance workflows, documented service-level agreements, and safety controls comparable to hardened production namespaces, whereas DIY cleaning gives you direct control over scheduling, resource allocation, and cost optimization, analogous to managing your own cluster infrastructure.

You’ll need to compare these options by quantifying reliability, security of physical access, impact on panel performance metrics, and total cost of ownership over time.

Pros of Professional Cleaning:

Although DIY maintenance may appear sufficient for basic debris removal, engaging professional cleaning services for solar panels provides measurable advantages regarding operational reliability, safety, and performance validation, comparable to how managed services harden and optimize a Kubernetes cluster in production.

Professionals apply expert techniques that standard tools can’t replicate, improving cleaning efficiency while preserving panel coatings and sealants. They also implement strict safety protocols that minimize fall risk and electrical hazards, aligning with lockout and tagging practices in data centers. Typically, you gain:

- Detailed inspection workflows that identify microcracks and hotspots early.

- Documented maintenance strategies, including frequency, methods, and approved agents.

- Instrumented performance verification, with pre‑ and post‑cleaning output metrics.

- Higher customer satisfaction through predictable uptime and validated warranty compliance.

Pros of DIY Solar Panel Cleaning:

By handling routine solar panel cleaning yourself, you retain direct operational control over schedule, tooling, and validation steps, similar to how an in‑house DevOps team manages day‑to‑day Kubernetes cluster hygiene without relying on external providers.

You minimize service costs while selecting cleaning equipment options that match manufacturer specifications and your risk tolerance. By applying targeted solar maintenance tips, you can standardize best cleaning techniques, document procedures, and keep an auditable history of each intervention.

DIY control also lets you enforce safety precautions such as lockout‑tagout, insulated extension poles, and nonconductive footwear, reducing operational exposure. Because you directly observe contamination and local weather, you can tune frequency recommendations and integrate these routines into ongoing, secure asset‑management workflows, including inverter inspections, wiring checks, and production‑monitoring reviews.

Frequently Asked Questions

How Does Cleaning Frequency Vary in Coastal, Desert, and Urban Environments?

You’ll adjust cleaning frequency by environment: higher coastal frequency mitigates salt corrosion on panel connectors, while desert challenges require shorter intervals due to abrasive particulates affecting sensor housings and cable jackets. Urban dust necessitates moderate, periodic cycles aligned with pollution peaks. You should integrate satellite soiling analytics, climate impact assessments, and SCADA alerts into automated maintenance schedules, then document procedures in your Kubernetes cluster runbooks and IT patch windows.

Are There Smart Sensors That Automatically Signal When Panels Need Cleaning?

When panels become less visually pristine, you can deploy smart cleaning technology using IIoT sensors that trigger automated cleaning systems. You integrate solar panel monitoring endpoints into a Kubernetes cluster, expose metrics via Prometheus, then run sensor efficiency analysis with alerting rules. You’d secure telemetry using mTLS, NetworkPolicies, and RBAC, and, as maintenance best practices, you periodically validate thresholds, test alert flows, and audit sensor firmware integrity regularly and thoroughly.

How Does Cleaning Affect Solar Panel Warranty Terms and Conditions?

Cleaning directly affects warranty terms because you’ve got to prove warranty compliance by following manufacturer guidelines and documenting approved cleaning methods. You maintain detailed maintenance records, including timestamps, procedures, detergents, and access controls, similar to Kubernetes audit logs. If you deviate from specified processes without impact assessment, the vendor can classify damage as customer-induced, void coverage, and deny replacements.

What Safety Certifications Should a Solar Panel Cleaning Product or Tool Have?

You should, in telegraph-era fashion verify that any photovoltaic cleaning tools and chemicals comply with IEC and UL safety standards, hold relevant CE or NSF product certifications, and document user guidelines, much like you’d audit Kubernetes admission controllers. You must assess grounding, insulation, and IP ratings, evaluate environmental impact and material safety data, then implement role-based access, logging, and change-control procedures before authorizing operators to use or maintain the equipment.

Can Drones Be Effectively Used for Cleaning Large Commercial Solar Installations?

Yes, you can use drones effectively for large commercial solar installations when you treat them as hardened drone technology endpoints, integrate them with automated solutions, and enforce strict RBAC-controlled maintenance schedules. You orchestrate flight plans via Kubernetes-native workloads, secure telemetry with mTLS, and log all actions centrally, improving cost efficiency and reducing environmental impact, while enforcing CIS-aligned policies, image signing, and continuous vulnerability scanning for all control software, infrastructure components.

Conclusion

You evaluate dry and wet cleaning methods using criteria comparable to Kubernetes maintenance policies, including risk scoring, resource allocation, and availability targets. By defining intervals, enforcing safety controls, and documenting each operation, you maintain every array in a known state, every module with validated access paths, every contaminant as an identified defect. You then select the method that maximizes energy yield, reduces operational exposure, and preserves asset life within explicit regulatory and environmental boundaries, constraints.